EXKLUSIVE: Thermographic and electroluminescence check and analysis

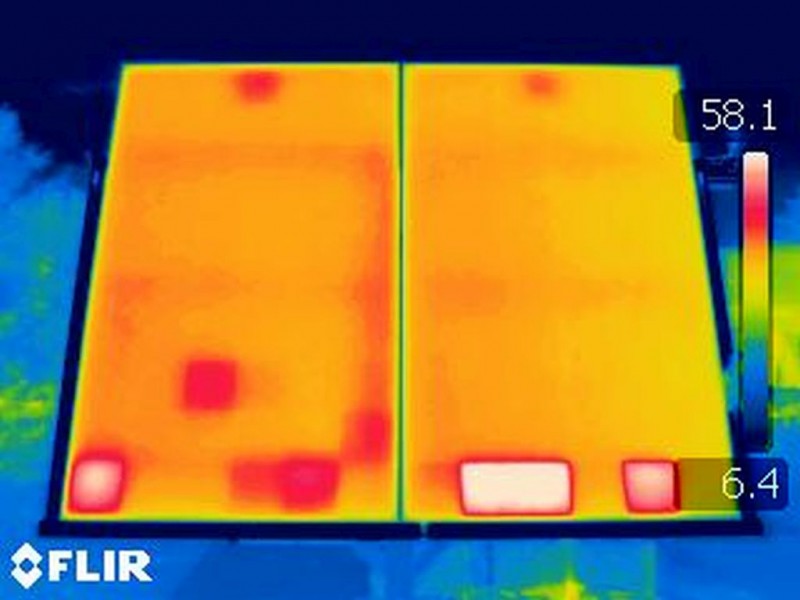

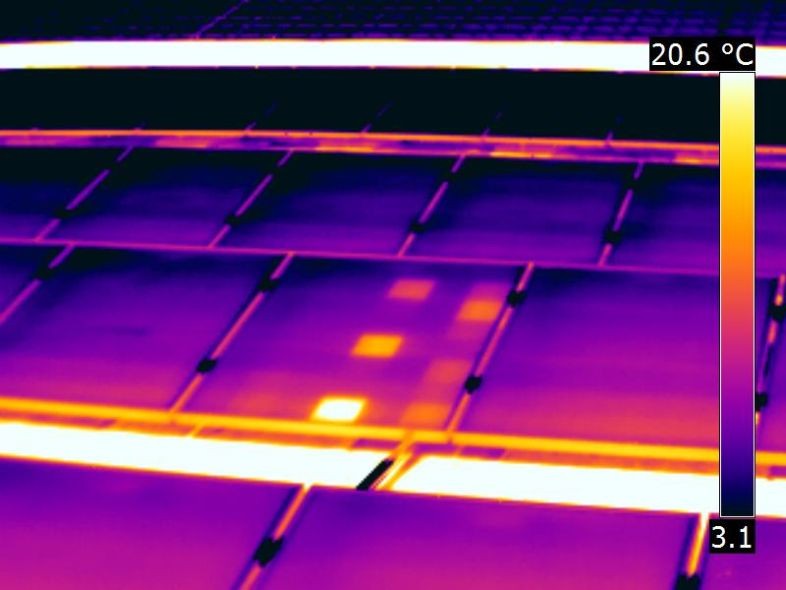

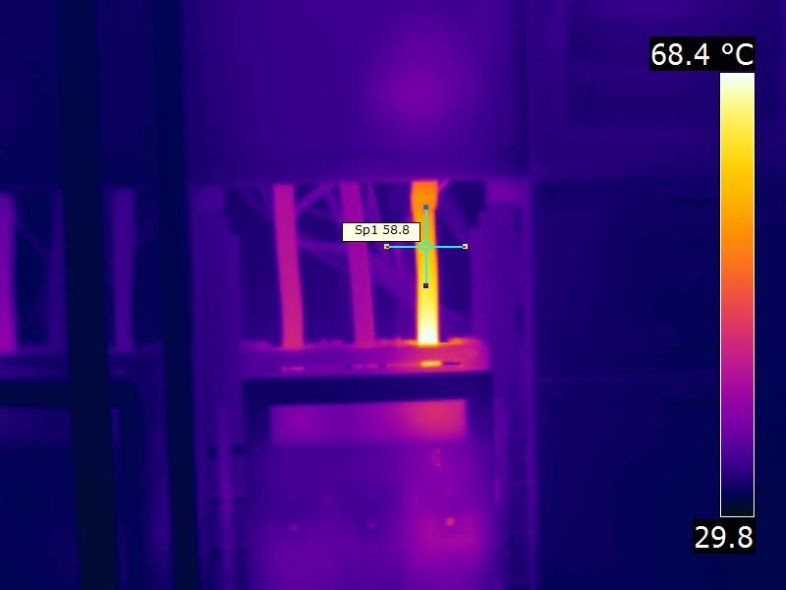

Undiscovered vulnerabilities in your building or its electrical system result in increased energy costs, and may have serious consequences. Furthermore, thermally conspicuous locations might indicate irregularities in photovoltaic systems. Electrical equipment allows quick identification of overheating components and dangerous transition resistances. Using our latest thermographic and infrared instruments, we examine your building, the photovoltaic system with all its components, or the electrical systems and equipment. This is duly recorded and the weaknesses identified. Our analysis identifies potential vulnerabilities and, more importantly, provides a tailored response plan. Take advantage of the cost-effective approach to implement an early response.

Further to thermal image technology, we have specialised in electroluminescence measuring (EL-measurement).

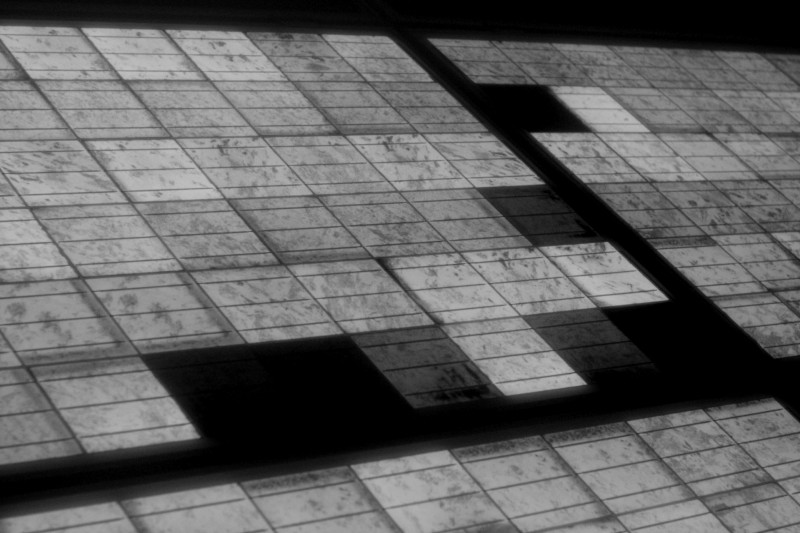

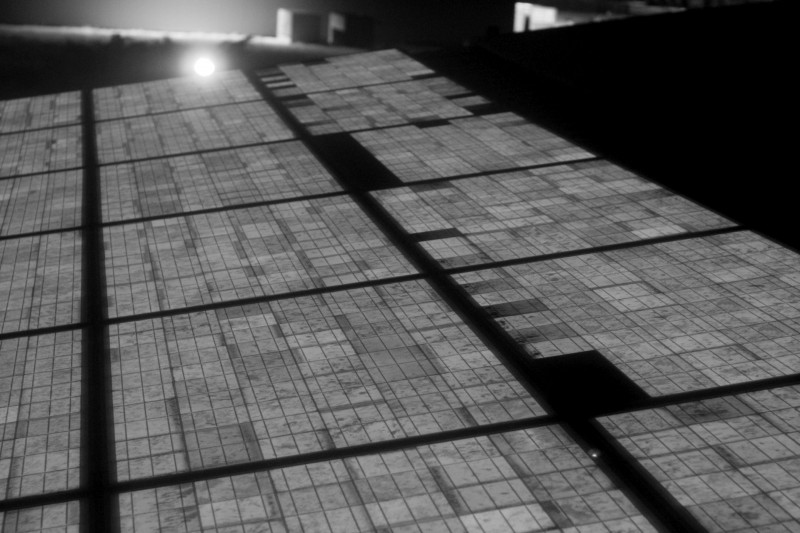

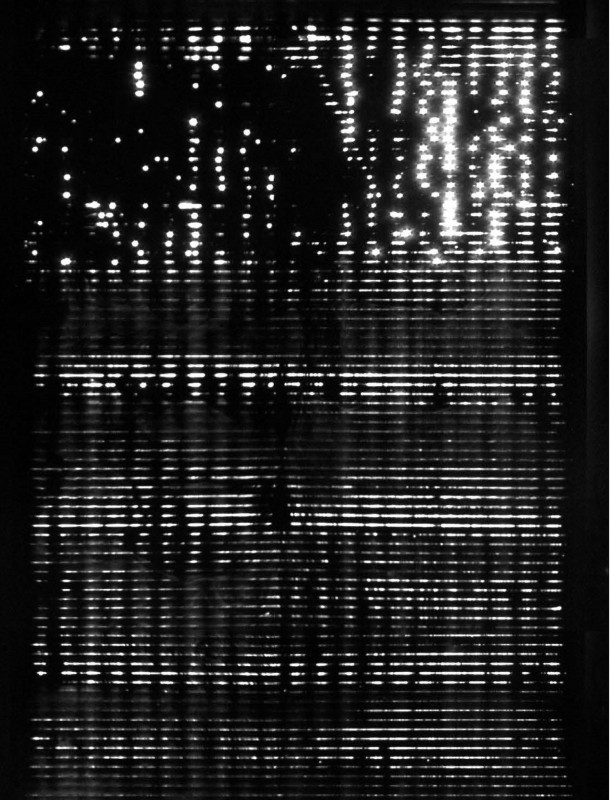

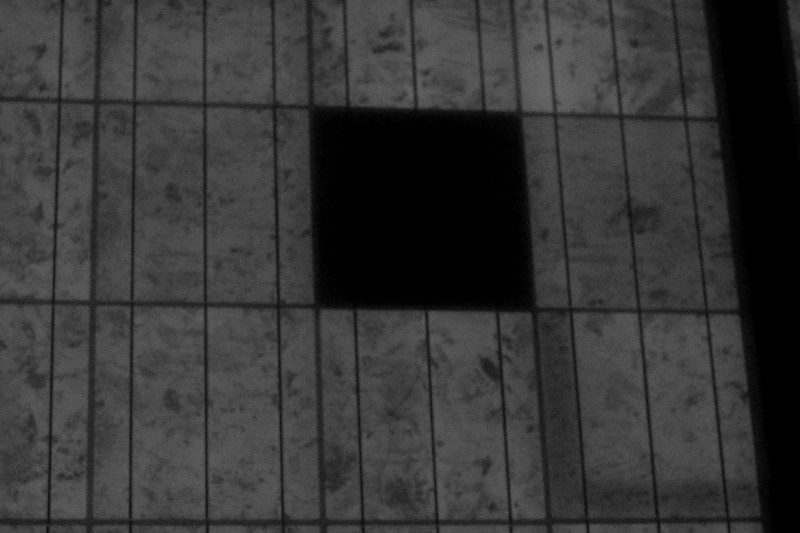

In greatly simplified terms, a reverse current a is generated through the photovoltaic modules by means of DC generator. Thus, the photovoltaic effect of the cells is reversed. Instead of producing electricity and heat from sunlight, the cells generate heat and light. This light is then captured with a special camera equipment for electroluminescence, and rendered thus visible. However, this is only possible in absolute darkness. These images reveal cracks, breaks, defects or damage in the individual modules and cells, which are not otherwise identifiable or metrologically detectable to the human eye. What is more, these images show patterns on the roof, which can provide clues to the general cause.

EL-measurement helps reveal various damages and defects in photovoltaic modules, such as:

- Damage due to cell rupture during manufacturing, transportation, installation, or resulting from other external influences, e.g., hail

- Defective bypass diodes or their failures arising, from example, from overvoltage, thermal runway, wear or moisture penetrating into the junction box

- PID - potential-induced degradation, which leads to a gradual decline in performance of the affected modules

- Corrosion

- String and cell failures

Up to now, modules had to be examined in the laboratory to detect the above-mentioned damage and defects. This method entails significant costs and risks arising from the dismantling, transportation to the laboratory and back, and final reassembly.

We have expanded and refined our measurement technology so that we can carry out EL measurements of entire systems, modules or even individual cells when installed on site, whereby the costs and risks of the analysis are significantly reduced.

Accordingly, we can recognise defective strings, modules and cells with a few pictures, supporting thus a targeted and effective repair and maintenance of your PV system. This allows uncovering damage caused, for example, by overvoltage, hail or product defects, whereby the considerable follow-up costs of failure and possible hazards can be avoided.

EL pictures can only be taken in total darkness. With our mobile, outdoor electroluminescent video camera, we have a fast an efficient way to take meaningful, efficient and high-resolution electroluminescent pictures, as well as to shoot video.

Particularly suitable for residential and commercial system operators, institutions, business, industry, insurance, etc.